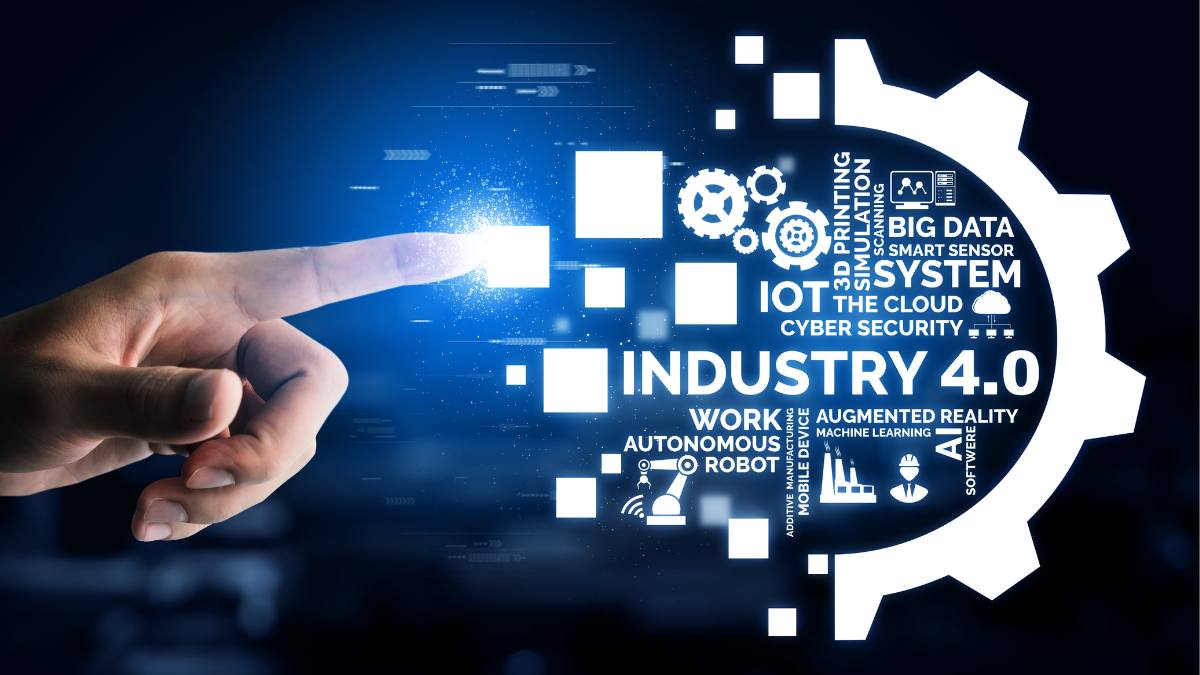

The term “4.0” is often used to refer to the fourth industrial revolution, which is a current trend in automation and data exchange in manufacturing technologies. This is in contrast to the previous three industrial revolutions, which were characterized by the use of steam power, electricity, and digital technologies, respectively.

One of the key differences between 4.0 and the previous industrial revolutions is the integration of artificial intelligence and other advanced technologies into the manufacturing process. This allows for a higher degree of automation and the ability to process vast amounts of data in real-time, enabling more efficient and intelligent decision-making.

Another significant difference between 4.0 and previous industrial revolutions is the increased focus on connectivity and the use of the Internet of Things (IoT) to link together various devices and systems. This allows for the seamless exchange of data and the ability to monitor and control the manufacturing process remotely.

Additionally, 4.0 is characterized by a greater emphasis on sustainability and environmental responsibility. This is reflected in the development of new technologies that aim to reduce waste and minimize the environmental impact of manufacturing.

Overall, 4.0 represents a major shift in the way that manufacturing is carried out, with a focus on greater automation, connectivity, and sustainability. This has the potential to greatly improve the efficiency and productivity of the manufacturing industry, but it also presents challenges and opportunities for workers and society as a whole.